Steam capacity: 0.5-4Ton/h

Working Pressure: ≤1.25MPa

Fuel Type: Coal, Wood Chips, Wood Logs, Sawdust, Rice Husk, Sugarcane Bagasse, etc.

Application: Textile, Garment, Food & Beverage, Cement Curing, Disinfection, etc.

DZH series coal/ biomass fired boiler is a fixed chain grate type boiler, that burner biomass, wood, coal. It can realize super-low pollution with the use of special dust collectors and air purification devices (water film dust collector, bag type static electricity dust collector, double towers desulfurization, etc.). Because of its steady performance and low fuel consumption, make it is popular in the market.

Textile, Garment, Food & Beverage, Chemical Industry, Cement Curing, Disinfection, etc.

High Quality Control: In manufacturing processes, we have adopting steel strength test, automatic steel cutting/ plate rolling/ welding, 100% x-ray welding check, magnetic particle check c-scan ultrasonography check, fluorescent penetrating check, hydraulic (water) pressure test, boiler thermal efficiency tested, to make sure all finished products are qualified.

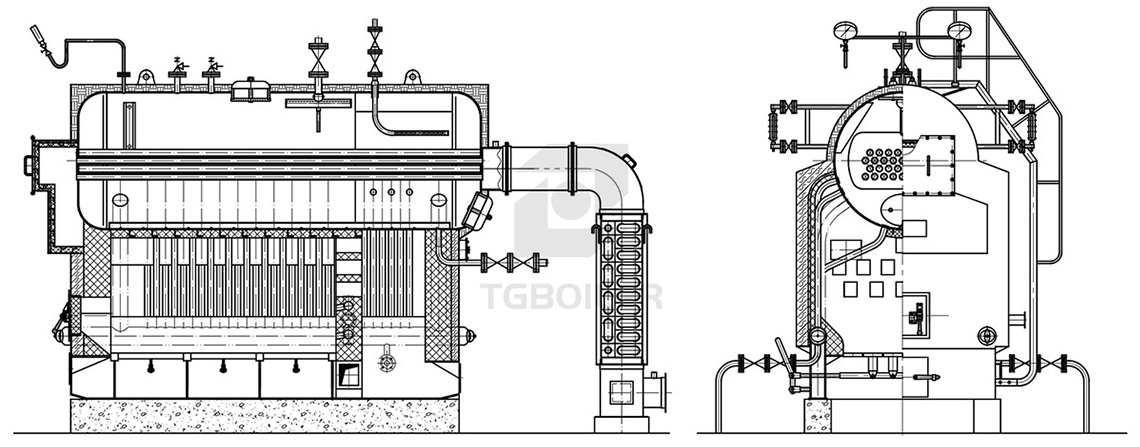

Simple Structure: DZH boiler adopting threaded fire tubes, single water drum, horizontal shell type boiler with 3 fire-passes structure, water-tube fire-tube mix design. Most important, the combustion fixed chain grate can also suit any kind of biomass. The small flakes chain grate can reduce fuel leakage, and also let the broken chain grate flakes is convenient of replace.

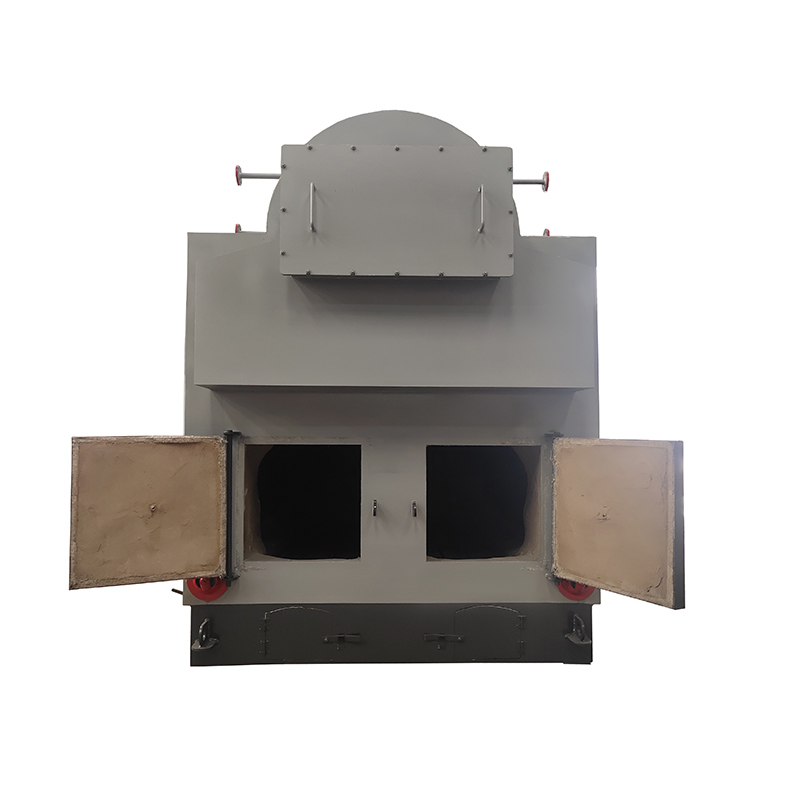

Better Adaptability On Fuels: Comparing with the DZL boiler, the DZH boiler has better adaptability on fuels, it can fire coal, rice husk, nutshell, sawdust, waste wood pieces, also can firewood logs, straws. But, the DZH boiler can only support manual fuel feeding and manual ash removal.

Safe Operation: DZH series is equipped with automatic water-level control, automatic pressure control, automatic interlock chain stop protection, free settable working pressure, visible system’s working states on screen.

| Model | DZH0.5-T | DZH1-T | DZH2-T | DZH3-T | DZH4-T | DZH6-T | |

| Capacity | kg of steam per hour | 500 | 1000 | 2000 | 3000 | 4000 | 6000 |

| HP | 32 | 64 | 128 | 256 | 256 | 384 | |

| Pressure | Bar | ≤10 | ≤10 | ≤13 | ≤16 | ≤16 | ≤16 |

| Steam Temperature | ℃ | ≤184 | ≤184 | ≤194 | ≤204 | ≤204 | ≤204 |

| Available Fuels | / | Wood pieces, Firewood Logs, Sawdust, Biomass pellet, Coal, Bagasse, Grain shell, Nuts shell, Palm shell, etc. |

|||||

| Thermal Efficiency | % | >75 | |||||

| Combustion Method | / | Fixed chain type chamber burning, Manual fuel feeding, Manual ash removing |

|||||

| Dimension | mm | 3228×2000×2656 | 4108×2200×2915 | 4700×2300×3270 | 5400×2450×3563 | 5600×2550×3563 | 6300×2750×3750 |

| Weight | kg | 8000 | 12000 | 15000 | 22000 | 22000 | 28500 |